embedded vision _ Integration of professional image processing

• Cost efficient

• Flexibly scalable

•Made in Germany

There are endless uses in image recognition. Whether for quality assurance, temperature measurement, object recognition or to support machine learning.

Just in time for Embedded World 2021, there are new solutions with powerful NXP microcontrollers, as modules, single board computers or gateways, which now make your implementation of camera sensors with AI a success.

Our embedded vision experts can be contacted directly via Zoom for your questions during the Embedded World.

The newest Board-level cameras:

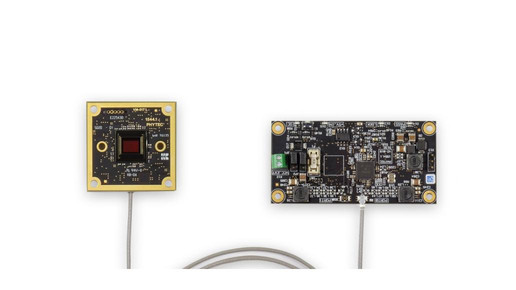

phyCAM®-L

FPD link ||| Board level camera

up to 15 m cable for MIPI CSI-2 systems

Learn more...

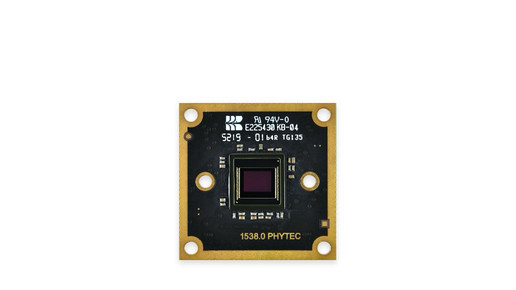

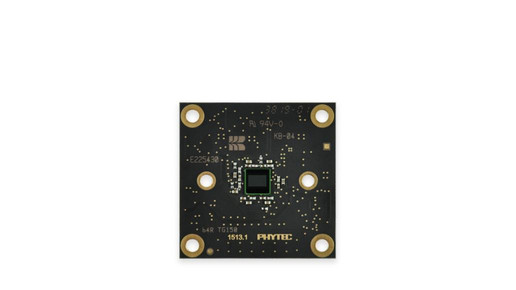

phyCAM®-mini VM-117

Smallest industrial S-mount board-level camera

for MIPI CSI-2 systems 18 x 26 mm

Learn more...

The latest i.MX 8 Processing systems:

phyCORE®-i.MX 8M Plus

Our newest processor module

for embedded imaging and AI on the edge.

Learn more...

phyBOARD®-Pollux (i.MX 8M Plus)

SBC for vision systems with i.MX 8M Plus

and two phyCAM-M MIPI CSI2 interfaces

Learn more...

phyCONTROL®-Ain (i.MX 8M Plus)

Flexible “Ready-to-go” top hat rail calculator

with phyCAM-L and phyCAM-M camera inputs

Learn more...

Martin Klahr

Head of Digital Imaging

Heiko Fendrich

Head of Digital Imaging

Request meeting for later by email: contact@phytec.de

Call via the hotline:

+ 49 (0) 6131 / 9221-32

Start your Zoom conversation with the experts here

System construction kit `` detect '' _ Flexible components for implementing embedded vision

Thanks to our preliminary work, you can integrate cameras as easily as sensors. This "add-in" instead of "add-on" significantly increases the synergies within the application and thus the cost efficiency of series products. Simplify solutions and add new functionality to your application. When series costs and long-term availability are taken into account, embedded systems offer convincing advantages.

Coordinated system solutions

With the phyCAM concept from PHYTEC, the requirements of a compact, tailor-made system solution can be easily met. The standardized phyCAM interfaces enable the combination of scalable microcontroller modules with coordinated image processing components. This creates a complete system that is ideally adapted to the application.

Flexibility - the key to an individual series

In addition to image acquisition, other functions are required. For example engine controls, GPS, audio, CAN or I / O lines. There is also the need to adapt the hardware to the given mechanical dimensions. The application-specific base board covers exactly these requirements. This customization option is an essential part of our concept. It distinguishes it from conventional, prefabricated components.

Interface to the software

The connection of the hardware to the application software is already prepared at the operating system level with the phyCAM concept. The drivers required for the camera sensor and controller camera interface are integrated in our BSPs. Under Embedded Linux, the V4L2 interface is the interface to the application software.

Develop application software easily

The phyCAM interface makes image data available to the application software in a simple manner. Further processing of the data can be implemented quickly and efficiently using ready-made image processing libraries.

Our lifecycle strategies enable product maintenance and ensuring delivery capability over the product lifecycle. This includes, for example, obsolescence management as well as update and security concepts. In this way, we guarantee you a product that will function over the long term.

Software _ Advantages of all PHYTEC hardware components

phyBSP

By the PHYTEC Board Support Package your project benefits from an extensive infrastructure Update & Device Management, integrated Security Features and daily tested Yocto release versions.

Extra-Services

In many areas of development, our Hardware and software experts Accelerate your development and maintenance and lead safely to success.

design service _ Hardware as individual as your project

Embedded hardware fully exploits its advantages in series production, especially when it is perfectly adapted to the target system.

The efficient means for this is the project-specific base board, which can be freely adapted to the requirements of your project.

If you have any questions about optics and lighting, image resolution and computing power, we are your perfect contact to bring together the right components with your ideas in terms of functions, device size, power consumption and, last but not least, economic factors.

Describe your task to us - we will outline your individual embedded vision solution with you. By using our pre-developed components such as camera and processor modules, our circuit diagram library and the experience of our engineers from hundreds of projects, the development of individual hardware is more cost-effective than you might think.

Martin Klahr

Head of Digital Imaging

Heiko Fendrich

Head of Digital Imaging

Meeting for later

inquire by email:

contact@phytec.de

Call via the hotline:

+ 49 (0) 6131 / 9221-32